Whether you are an occasional welder or a professional experienced one, WPS will play a key role everytime you need to perform a weld. In a trade like Welding, attention to detail and specifications is crucial, so every welder must be really clear on all the details a weld requires.

The main objective of a WPS is to serve as a guide that allows the welder to perform welds that are safe, repeatable and efficient. In other words, they serve as the manual you need to follow to perform a high quality weld.

What is a WPS?

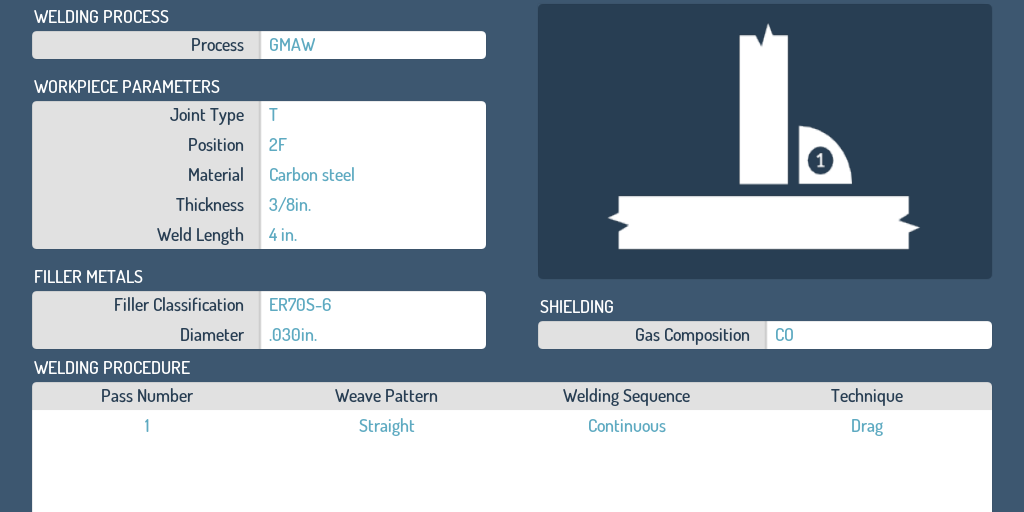

A WPS or Welding Procedure Specification is the written document that contains all the information a welder requires to start a welding process. Position, gas, technique, base material, filler metals… are some of the variables that must be featured. A WPS may seem confusing and difficult to understand for new welders, but it is one of the most relevant documents in the welding field and that is why they are an important part of welding training. How should it be written? The best way to do it is using an example of a real WPS and following these steps:

-

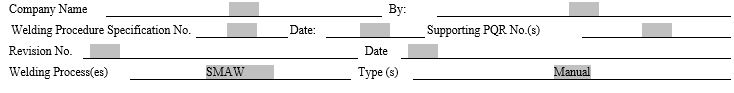

Basic Information:

All the basic information about the welding procedure:

- Name of the company and person who developed it

- Specification number and date

- Most WPS will be backed on a PQR (Procedure Qualification Record), you should refer to it in order to make it easy to trace the document back.

- Number and date of the last revision

- Welding processes and type

-

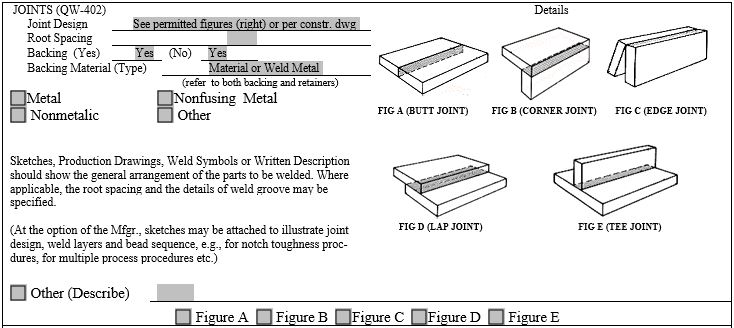

Joints:

Details of the joint design, including root spacing and backing (if the joint needs it and the backing material). This information should feature a graphic representation of the joint to make it easier for the welder.

-

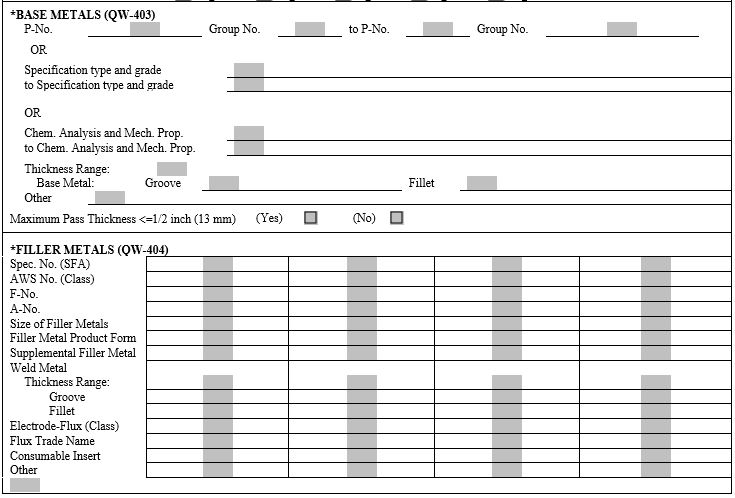

Base and filler metals:

Information about the base and filler metals that are going to be used in the welding procedure. You should specify the weld type (fillet or groove) and the thickness range of the base metal.

-

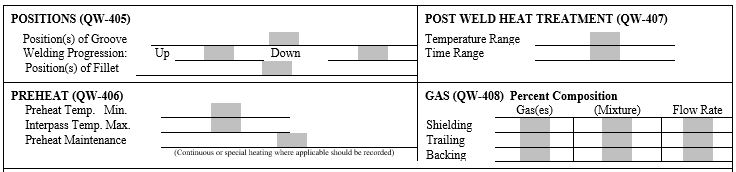

Additional details:

Pre and post weld heat treatment required, gas used and the positions in which the procedure will be performed. The welding progression should be specified if it is required.

-

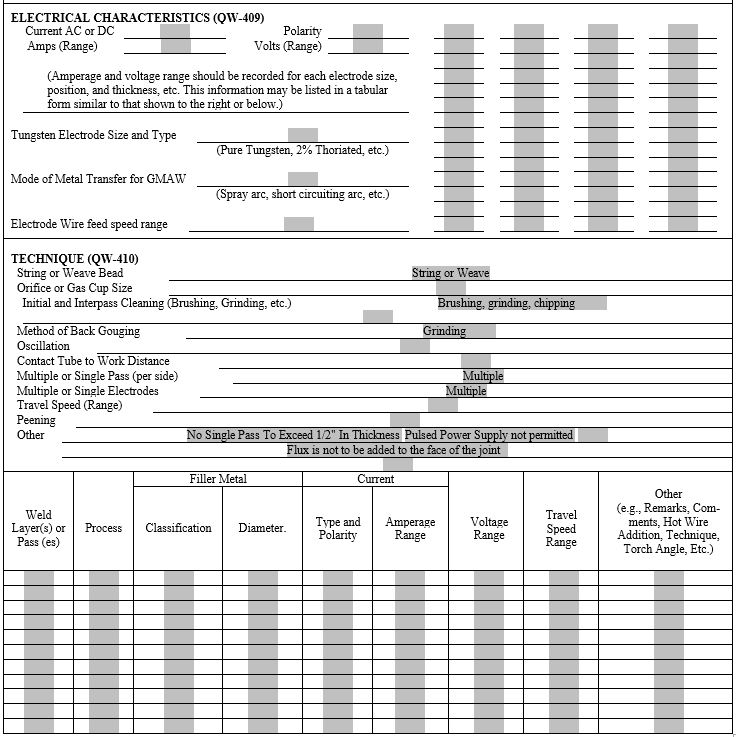

Electrical characteristics:

Information about each weld pass, including:

- Process

- Filler metal classification and diameter

- Current type and polarity

- Amps range

- Wire feed speed range

- Energy of power range

- Volts range

- Travel speed range

- Other electrical specifications

-

Technique:

- String or weave bead

- Orifice, nozzle or gas cup size

- Initial and interpass cleaning

- Method of back gouging

- Oscilation

- Contact tube to work distance

- Multiple or single pass (per side)

- Multiple or single electrodes

- Electrode spacing

- Peening

- Other

Knowing how to write and understand a WPS is key in welders’ training, that’s why real WPS can be introduced in the Soldamatic Augmented Training welding simulator. This way trainees can learn how to understand a WPS and subsequently practice that same procedure with Augmented Reality.

Why do you need a WPS?

The Welding Procedure Specification is a crucial document for a company and its quality standards. It is not just a document with all the information that the welder requires, but it is also the guideline to guarantee that the weld will follow the high quality standards required.

From the welder’s perspective, the WPS will provide all the information needed to perform the weld, so the first step any welder should take is going through the document and make sure all the specifications are understood and followed.

For companies, WPSs are so important that they are legally required in certain industries to make sure a tested and safe weld is performed, it would be accurate to say that they are not only a quality requirement but also a legal one!